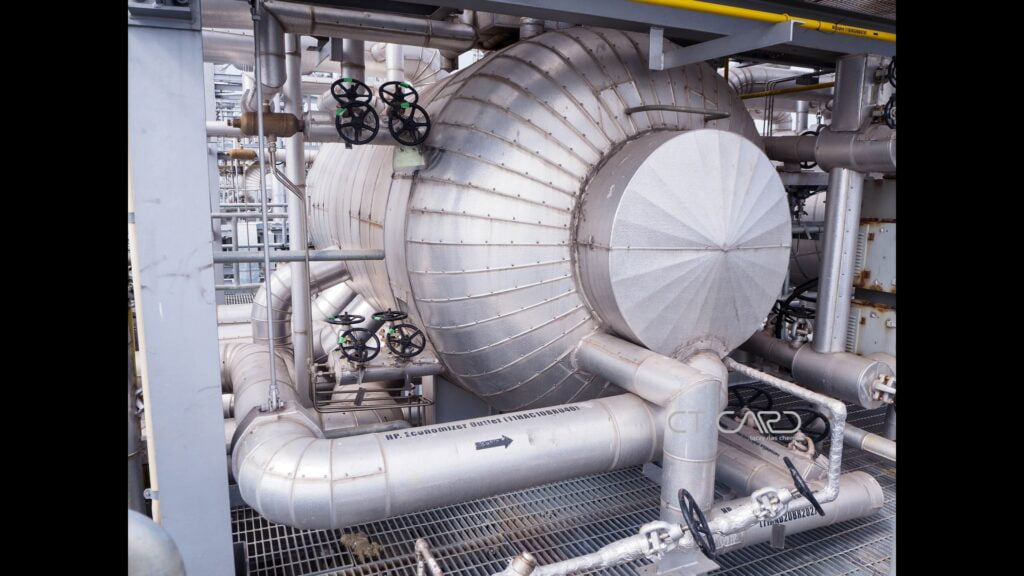

The operation of a boiler system is associated with the need to meet a number of water standards. Comprehensive operation of boiler circuits AquaCode®KCK means properly selected water preparation technology and multi-layer process monitoring. We ensure safe, efficient, trouble-free, but also economical operation of the boiler system.

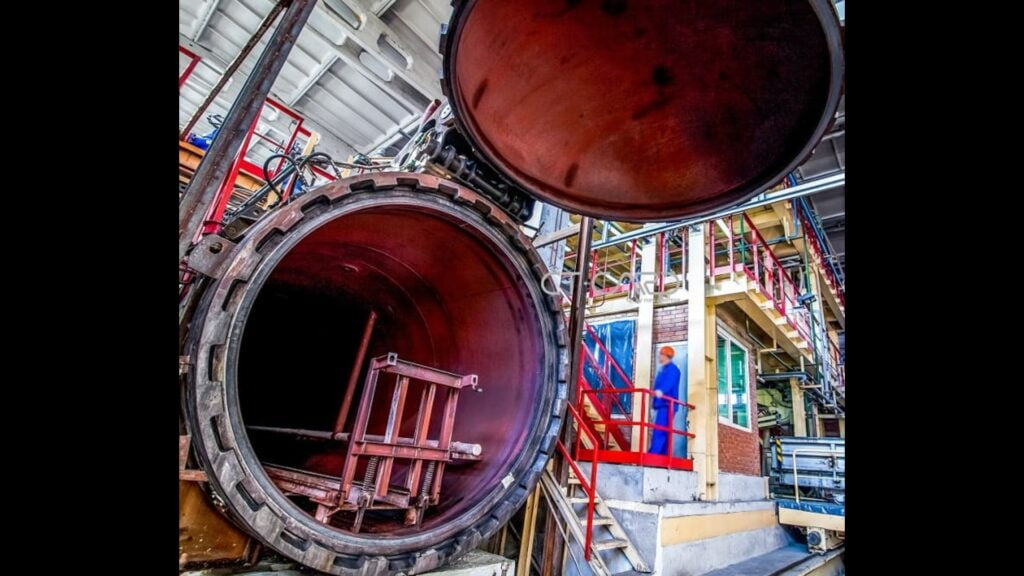

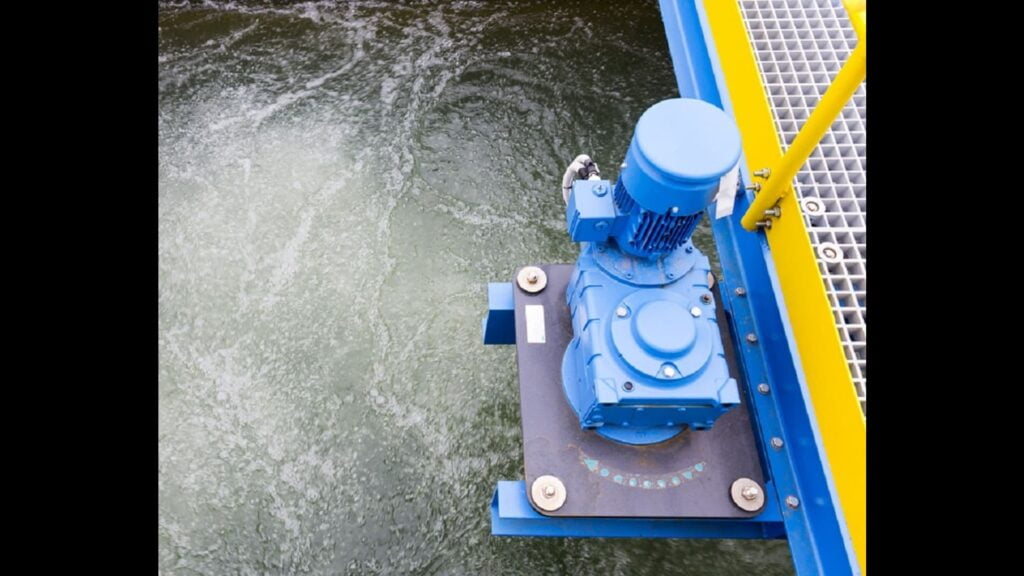

Cooling water treatment is carried out to reduce the formation of mineral deposits, corrosion and biological and mechanical contaminants.

Process water quality has a significant impact not only on operating costs, but also on the reliability of all types of refrigeration equipment.

The correct operation of these systems depends on the degree of water treatment, and thus on the cleanliness of the various parts of the systems and fittings.

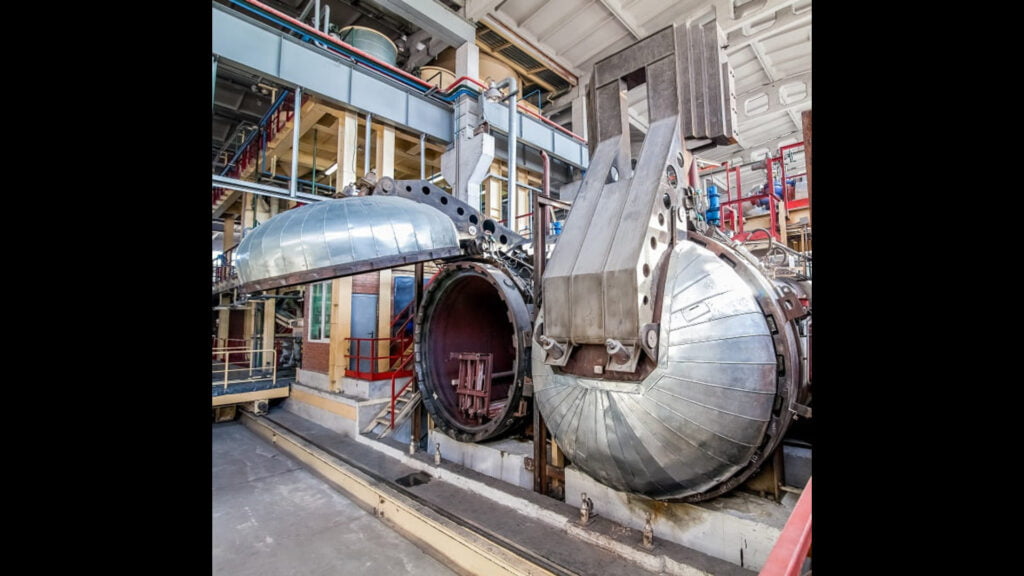

Formulations developed for tunnel pasteurizers and food sterilizers to provide corrosion protection for equipment, as well as can and bottle lid materials.

Control of processes to stop corrosion, deposits and discoloration.

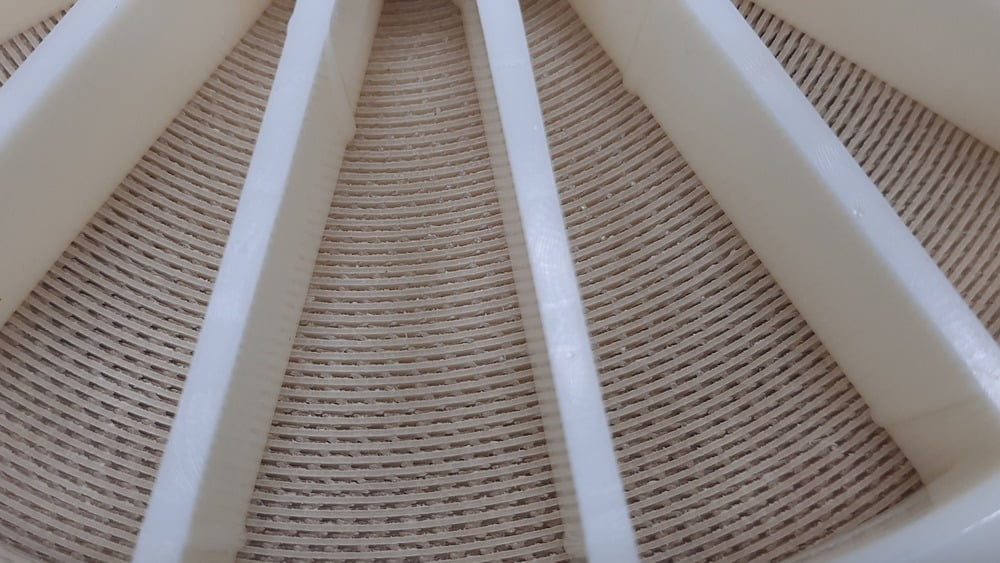

Antiscalants, a group of preparations for the protection of osmotic membranes, whose task is to protect and prevent crystallization of salts during the process. As a result, the membranes do not become limescale and clogged with sediment.

Membranes do not clog and work longer and more efficiently, extending the life of the RO filter station.

Chemical preparations for cleaning reverse osmosis (RO) membranes.

Removal of inorganic sludge: agents that dissolve or dissolve and disperse inorganic deposits such as calcium, magnesium, iron, silica and others.

Organic sediment removal: agents that dissolve or dissolve and disperse organic deposits, such as algae, bacteria, viruses and others.

Removal of biofilm deposits: preparations that dissolve or dissolve and disperse deposits from the biofilm, a layer of bacteria and other microorganisms that can form on the membrane surface.

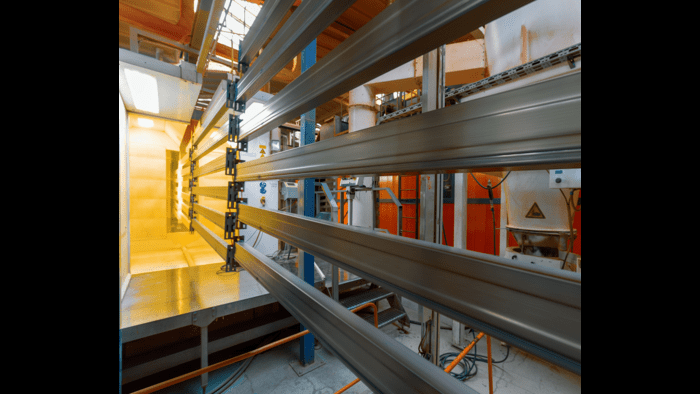

Formulations dedicated to water filtration systems where it is necessary to emphasize sediment separation processes through sendimentation and flocculation in industry. Flocculation treatment of waters containing oily and/or fatty emulsions of vegetable, animal or synthetic origin, in the thickening of sludges from food processing (slaughterhouses, dairies, canneries, farms, paper mills, etc.) or industrial (petrochemical, mechanical, electroplating, car washes, paint shops, etc.).

Flocculants for sludge thickening and dewatering.

The use of Flocculants (polyelectrolytes) in wastewater treatment is the process of the final element of coagulation, in which chemical bonds are formed between micelles.

The micelles combine and turn into a sludge or slurry, which is much easier to remove and clean. Flocculants for sludge dewatering and thickening are polymeric substances with varying ionic charges.

Formulations provide an effective reaction with the molecules of solvent-based and water-based paints that have entered the water. Coagulants that support water curtains in the spray booth, protecting them from disruption and loss of a homogeneous water film.

They reduce the amount of water that is needed to separate the paint particles.